CALEDONIAN

Professional Cable Provider

Quick Contact

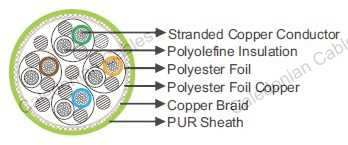

These cables are designed for the most extreme requirements in the industry and other heavy-duty environments in torsion applications.

| Conductor | Bare copper 19×26AWG. |

| Insulation | PO. |

| Cable Element | Double core. |

| Shielding | Polyester tape over stranded bundle. |

| Screen 1 | Polyester foil copper, bare. |

| Screen 2 | Copper braid. |

| Sheath | PUR |

| Operating Temperatures | -20℃~+80℃ |

| Minimum Bending Radius | 80mm |

| Impedance @1~100MHz | 100Ohm +/-15% |

| Nominal Mutual Capacitance | 50nF/km |

| Attenuation @10MHz | <1.3dB/100m |

| Attenuation @16MHz | <1.6dB/100m |

| Attenuation @62.5MHz | <3.2dB/100m |

| Attenuation @100MHz | <4dB/100m |

| Next @10MHz | 47dB |

| Next @16MHz | 44dB |

| Next @62.5MHz | 35dB |

| Next @100MHz | 32dB |

| ACR @10MHz | 45.7dB |

| ACR @16MHz | 42.4dB |

| ACR @62.5MHz | 31.8dB |

| ACR @100MHz | 28dB |

| Flame Retardant | IEC 60332-1 |

| Halogen Free | IEC 60754 |

| Smoke Density | IEC 61034 |

| Oil Resistant | Yes |

| UV Resistant | Yes |

| CONSTRUCTION | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT |

|---|---|---|

| NO. OF CORES×MM2 | MM | KG/KM |

| 4×2×0.64 | 7.5 | 79 |