CALEDONIAN

Professional Cable Provider

Quick Contact

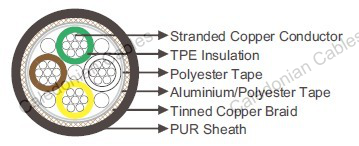

These cables with its oil-resistant PUR sheath and increased temperature resistance are employed in the wind turbine area and similar sectors for monitoring wind speed, temperature and performance parameters.

| Conductor | Stranded bare copper 7×0.203 mm (Section 0.22 mm2) |

| Insulation | TPE compound. |

| Center Filler | Fibrillated polypropylene filler |

| Cable Element | Star quad. |

| Screen 1 | Polyester tape over stranded bundle. |

| Screen 2 | Aluminium/Polyester tape (Aluminium outside). |

| Overall Screen | Tinned copper braid. |

| Sheath | PUR compound. |

| Operating Temperatures | -25℃~+100℃ |

| Minimum Bending Radius | flexing: 10×OD; fixed installation: 5×OD |

| Impedance | 120Ohm +/-15% |

| Maximum Conductor Resistance @20°C | 98Ohm/km |

| Nominal Mutual Capacitance | 41nF/km |

| Minimum Insulation resistance | 1GOhm×km |

| Flame Retardant | EN 50265-2-1/IEC 60332-1 |

| Halogen Free | HD22.13/EN50267-1/IEC 60754 |

| Gases Corrosively | HD22.13/EN50267-2/IEC 60754 |

| Smoke Density | EN50268/IEC 61034 |

| Oil Resistant | Yes |

| Ozone Resistant | Yes |

| UV Resistant | Yes |

| CONSTRUCTION | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT |

|---|---|---|

| NO. OF CORES×MM2 | MM | KG/KM |

| 2×2×0.22 | 6.4 | 60 |