CALEDONIAN

Professional Cable Provider

Quick Contact

Used in dry, damp and wet places where there are mechanical effects, in mines, in trolley, systems, in cranes, in tunneling applications as trailing and cable power supply.

| Construction | DIN VDE 0250-813 |

| General Requirements | DIN VDE 0250-1 |

| Guide Use | DIN VDE 0298-3 |

| Electrical Tests | DIN VDE 0472-501, 503, 508 |

| Non-Electrical Tests | DIN VDE 0472-401. 402,602,303, 615 |

| Under Fire Condition Tests | DIN VDE 0472-803, 804 |

| Flame Retardant | VDE 0482-332-1-2,DIN EN 60332-1-2,IEC 60332-1 |

| Oil Resistant | HD/EN/IEC 60811-2-1.,DIN VDE0473-811-2-1 |

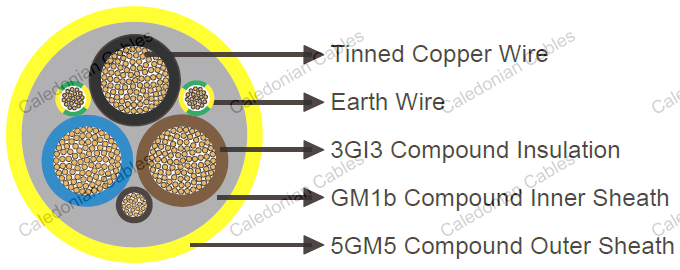

Conductor : Electrolytic,stranded,tinned copper wire DIN VDE 0295 class 5.

Insulation : All cores are insulated with 3Gl3 compound (acc. to DIN VDE 0207 part 20).

Lay Up : All cores are laid up in contact with each other and interstitial ground cores.

Inner Sheath : Special elastomeric compound CM1b (acc. to DIN VDE 0207 Teil 21).

Outer Sheath : Heavy-duty elastomer 5GM5 (acc. to DIN VDE 0207 Teil 21) Yellow or black.

| Rated Voltage | 0.6 / 1 KV |

| AC Test Voltage | 3KV |

| Operating Temperature | Max. 90°C |

| Short - Clrcult Temperature | Max. 250°C |

| Working Temperature | |

| Fixed | -40°C-+80°C |

| Mobile | -25°C-+80°C |

| Min Bending Radius | VDE 0298-3 Tab.3 |

| Current Carrying Capacities | VDE 0298-4 |

| Cross Section | Overall Diameter (min-max) | Appro. Weight |

|---|---|---|

| mm² | mm | kg/km |

| 3x25+3x25/3 | 40.0-44.0 | 2470 |

| 3x35+3x25/3 | 44.4-48.4 | 3150 |

| 3x50+3x25/3 | 47.7-51.7 | 3750 |

| 3x70+3x35/3 | 52.3-56.3 | 4690 |

| 3x95+3x50/3 | 59.9-63.9 | 6210 |

| 3x120+3x70/3 | 63.8-67.8 | 7430 |

| 3x150+3x70/3 | 69.2-73.2 | 8900 |

| 3x185+3x95/3 | 73.1-77.1 | 10330 |