M2XH 0.6/1 kV XLPE Insulated, LSOH (SHF1) Sheathed Flame Retardant Power & Control Cables (Multicore)

Applications

These unarmoured power & control cables are used on board of ships in all locations for fixed installations not subject to mechanical risk complying with IEC standards 60092-352. These cables are flame retardant, low smoke & halogen free.

Standards

- IEC 60092-350/351/353/359

- IEC 60332-1

- IEC 60332-3-22

- IEC 60754-1/2

- IEC 61034

Construction

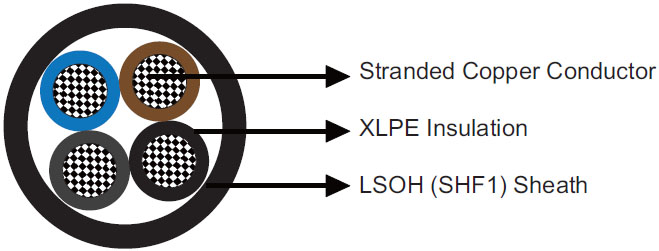

| Conductors |

Class 2 stranded copper conductor, round or sector shaped. |

| |

Class 5 stranded conductors can be offered upon request. |

| Insulation |

XLPE. |

| Filler (optional) |

Halogen free filling compound. |

| Outer Sheath |

LSOH (SHF1). |

Core Identification

| Two cores |

Blue, Brown. |

| Three cores |

Brown, Black, Grey. |

| Four cores |

Blue, Brown, Black, Grey. |

| Five cores |

Blue, Brown, Black, Grey, Black. |

| Multi cores |

White with black numbers. |

| With yellow/green (optional) |

| Two cores + earth (3G) |

Yellow/green, Blue, Brown. |

| Three cores + earth (4G) |

Yellow/green, Brown, Black, Grey. |

| Four cores + earth (5G) |

Yellow/green, Blue, Brown, Black, Grey. |

Mechanical and Thermal Properties

| Bending Radius for Fixed Installations |

6×OD (OD>25mm); 4×OD (OD ≤25mm) |

| Temperature Range |

-30℃ ~ +80℃ |

Dimensions and Weight

M2XH Multicore 0.6/1kV

| Part No. |

Construction No. of elements×No. of cores in element×Cross section |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Nominal Weight |

| |

mm² |

mm |

mm |

mm |

kg/km |

| M2XH -2C1.5 |

2×1.5 |

0.7 |

1.1 |

8.4 |

80 |

| M2XH -2C2.5 |

2×2.5 |

0.7 |

1.1 |

9.2 |

100 |

| M2XH -2C4 |

2×4 |

0.9 |

1.1 |

11.1 |

135 |

| M2XH -2C6 |

2×6 |

0.9 |

1.2 |

12.4 |

185 |

| M2XH -2C10 |

2×10 |

0.9 |

1.2 |

14.1 |

270 |

| M2XH -2C16 |

2×16 |

0.9 |

1.3 |

16.4 |

400 |

| M2XH -2C25 |

2×25 |

0.9 |

1.3 |

18.8 |

700 |

| M2XH -2C35 |

2×35 |

0.9 |

1.3 |

21.4 |

930 |

| M2XH -2C50 |

2×50 |

1.0 |

1.3 |

24.2 |

1290 |

| M2XH -3C1.5(3G1.5) |

3×(G)1.5 |

0.7 |

1.1 |

8.8 |

100 |

| M2XH -3C2.5(3G2.5) |

3×(G)2.5 |

0.7 |

1.1 |

9.8 |

130 |

| M2XH -3C4(3G4) |

3×(G)4 |

0.9 |

1.2 |

12.0 |

190 |

| M2XH -3C6(3G6) |

3×(G)6 |

0.9 |

1.2 |

13.2 |

250 |

| M2XH -3C10 |

3×10 |

0.9 |

1.3 |

15.2 |

380 |

| M2XH -3C16(3G16) |

3×16 |

0.9 |

1.3 |

17.5 |

560 |

| M2XH -3C25 |

3×25 |

0.9 |

1.5 |

20.7 |

875 |

| M2XH -3C35 |

3×35 |

0.9 |

1.6 |

23.5 |

1220 |

| M2XH -3C35S |

3×35 (sector shaped) |

0.9 |

1.5 |

20.1 |

1135 |

| M2XH -3C50 |

3×50 |

1.0 |

1.7 |

26.7 |

1780 |

| M2XH -3C50S |

3×50 (sector shaped) |

1.0 |

1.7 |

22.8 |

1530 |

| M2XH -3C70S |

3×70 (sector shaped) |

1.1 |

1.8 |

26.7 |

2150 |

| M2XH -3C95S |

3×95 (sector shaped) |

1.1 |

1.9 |

30.2 |

2900 |

| M2XH -3C120S |

3×120 (sector shaped) |

1.2 |

2.1 |

34.0 |

3675 |

| M2XH -4C1.5(4G1.5) |

4×(G)1.5 |

0.7 |

1.1 |

9.6 |

120 |

| M2XH -4C2.5(4G2.5) |

4×(G)2.5 |

0.7 |

1.1 |

10.7 |

165 |

| M2XH -4C4(4G4) |

4×(G)4 |

0.9 |

1.2 |

13.2 |

240 |

| M2XH -4C6(4G6) |

4×(G)6 |

0.9 |

1.2 |

14.5 |

320 |

| M2XH -4C10(4G10) |

4×(G)10 |

0.9 |

1.3 |

16.7 |

490 |

| M2XH -4C16(4G16) |

4×(G)16 |

0.9 |

1.4 |

19.5 |

740 |

| M2XH -4C25(4G25) |

4×(G)25 |

0.9 |

1.5 |

22.8 |

1145 |

| M2XH -4G35 |

4G35 |

0.9 |

1.7 |

26.0 |

1515 |

| M2XH -4G50 |

4G50 |

1.0 |

1.8 |

29.7 |

2340 |

| M2XH -5C1.5(5G1.5) |

5×(G)1.5 |

0.7 |

1.1 |

10.5 |

145 |

| M2XH -5C2.5(5G2.5) |

5×(G)2.5 |

0.7 |

1.2 |

11.9 |

205 |

| M2XH -5G6 |

5G6 |

0.9 |

1.3 |

16.1 |

400 |

| M2XH -5G16 |

5G16 |

0.9 |

1.5 |

21.6 |

920 |

| M2XH -6C1.5 |

6×1.5 |

0.7 |

1.2 |

11.6 |

180 |

| M2XH -7C1.5 |

7×1.5 |

0.7 |

1.2 |

11.7 |

195 |

| M2XH -8C1.5(8G1.5) |

8×(G)1.5 |

0.7 |

1.2 |

12.7 |

225 |

| M2XH -10C1.5 |

10×1.5 |

0.7 |

1.3 |

14.8 |

275 |

| M2XH -12C1.5 |

12×1.5 |

0.7 |

1.3 |

15.3 |

315 |

| M2XH -16C1.5 |

16×1.5 |

0.7 |

1.4 |

17.2 |

410 |

| M2XH -19C1.5 |

19×1.5 |

0.7 |

1.4 |

18.1 |

470 |

| M2XH -24C1.5 |

24×1.5 |

0.7 |

1.5 |

21.3 |

620 |

| M2XH -5C2.5 |

5×2.5 |

0.7 |

1.2 |

11.9 |

210 |

| M2XH -7C2.5 |

7×2.5 |

0.7 |

1.2 |

13.2 |

280 |

| M2XH -12C2.5 |

12×2.5 |

0.7 |

1.3 |

17.4 |

460 |

| M2XH -19C2.5 |

19×2.5 |

0.7 |

1.4 |

20.6 |

690 |

| M2XH -24C2.5 |

24×2.5 |

0.7 |

1.5 |

24.3 |

880 |

| M2XH -27C2.5 |

27×2.5 |

0.7 |

1.5 |

24.6 |

970 |

| M2XH -37C2.5 |

37×2.5 |

0.7 |

1.6 |

27.7 |

1300 |