| Windmill Cables | |||

| EPR/HFXLEVA LSOH 0.6/1kV Torsion Resistant Power Cable |

![]() Windmill Cables

Windmill Cables

Application

These cables are designed for use at medium mechanical stresses in wind turbines. They can be used in case of protected and fixed installation in tubes or in equipment as well as rotor connecting cable of motors with a working voltage up to 1000 V alternating voltage or a direct voltage up to 750 V against ground.

Standards

DIN VDE 0282 part 4

HD 22.4 S4

HD 22.1

BS 7919

IEC 60245-4

Construction

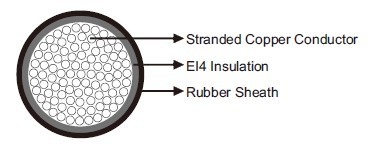

Conductor: Stranded bare copper conductor, class 5 acc. to IEC 60228/DIN VDE 0295.

Insulation: Rubber type EI4 according to HD 22.1/DIN VDE 0282 part 1.

Sheath: Rubber compound according to HD 22.1/DIN VDE 0282 part 1.

Technical Data

Rated Voltage Uo/U (Um) |

450/750V |

Operating Temperatures |

-30℃~+60℃ |

Minimum Bending Radius |

flexing:7.5×OD; fixed: 4×OD |

Maximum Permissible Tensile Load |

15 N/mm² |

Short-circuit Temperature |

250℃ |

Flame Retardant |

IEC 60332-1/DIN VDE 0472 part 804 |

Oil Resistant |

Yes |

Ozone Resistant |

Yes |

Weather Resistant |

Yes |

Dimensions and Weight

Construction |

Nominal Overall Diameter |

Nominal Weight |

No. of cores×mm² |

mm |

kg/km |

1×1.5 |

6.4 |

58 |

1×2.5 |

7.1 |

71 |

1×4 |

8.1 |

100 |

1×6 |

8.9 |

130 |

1×10 |

10.7 |

230 |

1×16 |

12.1 |

290 |

1×25 |

14.3 |

420 |

1×35 |

16.1 |

530 |

1×50 |

18.6 |

750 |

1×70 |

21.0 |

960 |

1×95 |

23.4 |

1250 |

1×120 |

25.7 |

1560 |

1×150 |

28.3 |

1900 |

1×185 |

31.0 |

2300 |

1×240 |

34.5 |

2950 |

1×300 |

37.7 |

3600 |

1×400 |

42.1 |

4600 |

1×500 |

46.7 |

6000 |

2×1 |

8.9 |

98 |

2×1.5 |

9.8 |

135 |

2×2.5 |

11.7 |

193 |

2×4 |

13.5 |

280 |

2×6 |

15.0 |

330 |

2×10 |

20.2 |

586 |

2×16 |

23.0 |

810 |

2×25 |

27.5 |

1160 |

3G1 |

9.5 |

130 |

3G1.5 |

10.6 |

165 |

3G2.5 |

12.5 |

235 |

3G4 |

14.5 |

320 |

3G6 |

16.1 |

420 |

3G10 |

21.7 |

810 |

3G16 |

24.7 |

1050 |

3G25 |

29.6 |

1250 |

3G35 |

33.2 |

1900 |

3G50 |

38.5 |

2600 |

3G70 |

43.4 |

3400 |

3G95 |

48.7 |

4450 |

3G120 |

53.7 |

5180 |

3G150 |

59.0 |

6500 |

3G185 |

64.5 |

7860 |

3G240 |

73.5 |

10224 |

3G300 |

81.0 |

12620 |

4G1 |

10.6 |

150 |

4G1.5 |

11.7 |

200 |

4G2.5 |

13.8 |

290 |

4G4 |

16.0 |

395 |

4G6 |

17.9 |

540 |

4G10 |

23.7 |

950 |

4G16 |

27.0 |

1260 |

4G25 |

32.8 |

1860 |

4G35 |

36.8 |

2380 |

4G50 |

42.6 |

3190 |

4G70 |

48.4 |

4260 |

4G95 |

54.7 |

5600 |

4G120 |

59.5 |

6830 |

4G150 |

65.5 |

8320 |

4G185 |

72.0 |

9800 |

4G240 |

81.5 |

12100 |

4G300 |

90.5 |

15200 |

5G1.5 |

12.8 |

240 |

5G2.5 |

15.2 |

345 |

5G4 |

17.8 |

485 |

5G6 |

19.9 |

650 |

5G10 |

26.0 |

1200 |

5G16 |

29.9 |

1550 |

5G25 |

36.2 |

2250 |

5G35 |

41.3 |

2750 |

5G50 |

45.4 |

3950 |

5G70 |

48.9 |

4740 |

7G1.5 |

16.0 |

375 |

7G2.5 |

18.3 |

520 |

7G4 |

21.4 |

681 |

12G1.5 |

20.0 |

460 |

12G2.5 |

23.4 |

760 |

18G2.5 |

27.7 |

850 |

19G1.5 |

23.5 |

810 |

19G2.5 |

28.3 |

1075 |

24G1.5 |

27.5 |

1015 |

24G2.5 |

32.6 |

1390 |

G: with green-yellow earth core

×: without green-yellow earth core