| Industrial Cables | |||

Industrial Cables

Industrial Cables

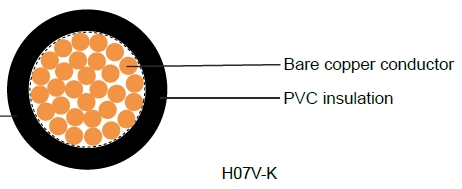

H07V-K

Application and Description

H07V-K cables are not suitable to be installed for laying in tubes, under and surface mounting of plaster and also

in closed installation conduits. These are not allowed to install for direct laying on cable trays, channel or

tanks. These types are permitted for the inner wiring of equipment, distributor and switchboards and also for

protective laying to the lightings with a nominal voltage up to 1000 V alternating current or up to 750 V direct

current against earth.

Standard and Approval

<HAR> HD 21.3 S3, VDE-0281 Part-3, CEI 20-20, CEI20-52,

CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant

Cable Construction

Fine bare copper strands

Strands to VDE-0295 Class-5, IEC 60228 Class-5

Special PVC TI1 core insulation

Cores to VDE-0293 colors on chart

Technical Characteristics

Working voltage: 450/750V

Test voltage: 2500 volts

Flexing bending radius: 12.5 x Ø

Static bending radius: 12.5 x Ø

Flexing temperature: -5º C to +70º C

Static temperature: -30º C to +80º C

Short circuit temperature: +160º C

Flame retardant: IEC 60332.1

Insulation resistance: 10 MΩ x km

Cable Parameter

AWG |

No. of Cores x Nominal Cross Sectional Area # x mm² |

Nominal Thickness of Insulation mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/Km |

Nominal Weight kg/Km |

1 x 1.5 |

0,7 |

3.1 |

14.4 |

20 |

|

14(50/30) |

1 x 2.5 |

0,8 |

3.6 |

24.0 |

31 |

12(56/28) |

1 x 4 |

0,8 |

4.3 |

38.0 |

48 |

10(84/28) |

1 x 6 |

0,8 |

4.9 |

58.0 |

69 |

8(80/26) |

1 x 10 |

1,0 |

6.4 |

96.0 |

121 |

6(128/26) |

1 x 16 |

1,0 |

8.1 |

154.0 |

211 |

4 (200/26) |

1 x 25 |

1,2 |

9.8 |

240 |

303 |

2 (280/26) |

1 x 35 |

1,2 |

11.1 |

336 |

417 |

1 (400/26) |

1 x 50 |

1,4 |

13.1 |

480 |

539 |

2/0 (356/24) |

1 x 70 |

1,4 |

15.5 |

672 |

730 |

3/0 (485/24) |

1 x 95 |

1,6 |

17.2 |

912 |

900 |

4/0 (614/24) |

1 x 120 |

1,6 |

19.7 |

1152 |

1135 |

1 x 150 |

1,8 |

21.3 |

1440 |

1410 |

|

350 MCM (944/24) |

1 x 185 |

2,0 |

23.4 |

1776 |

1845 |

500MCM(1225/24) |

1 x 240 |

2,2 |

27.1 |

2304 |

2270 |