| Industrial Cables | |||

Industrial Cables Single Core Fixed Wiring Cable

Industrial Cables Single Core Fixed Wiring Cable

Coil End Lead Cable to BS 6195 type 4

Application and Description

Coil End Lead Cable to BS 6195 type cables are designed as power leads for permanent connection to coil winding motors, panel

wiring and electrical machinery. They are able to withstand high temperature and immersion in varnish.

Other applications include vehicle wiring, The HOFR sheath resists oil and varnish and the stranding is

designed as a compromise between flexibility and positional stability. Also they are suitable for use as

an alternative to tri-rated and bi-rated cable in certain applications.

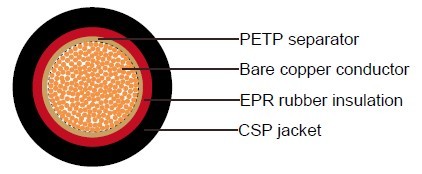

Cable Construction

Fine bare copper strands

Stranding to BS 6360 Class 5 or IEC 60228 Class 5

PETP(Polyethylene Terephthalate) tape separator

EPR-HOFR( Ethylene Propylene Rubber-Heat and Oil Resistant and Flame Retardant) insulation, type

FR1 (for type 4A & 4C) & type FR2 (for type 4D & 4E&4F) to BS 7655

CSP(Chlorosulphonated Polyethylene), HOFR (Heat and Oil Resistant and Flame Retardant) sheath

to BS 6899, black

Technical Characteristics

Working voltage: Type 4A: 300/500V

Type 4C: 600/1000V

Type 4D: 1900/3300V

Type 4E: 3800/6600V

Type 4F: 6350/11000V

Minimum bending radius: 4xOverall diameter

Operating temperature: -20º C to +90º C

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm | Nominal Overall Diameter mm |

Nominal Weight kg/km |

| TYPE 4A | ||||

| 18(24/32) | 1x0.75 | 0.8 | 3.5 | 16 |

| 17(32/32) | 1x1 | 0.8 | 3.7 | 19 |

| 16(30/30) | 1x1.5 | 0.8 | 4 | 25 |

| 14(50/30) | 1x2.5 | 0.9 | 4.6 | 37 |

| 12(56/28) | 1x4 | 1 | 5.4 | 57 |

| 10(84/28) | 1x6 | 1 | 6.5 | 80 |

| 8(80/26) | 1x10 | 1.2 | 7.9 | 130 |

| TYPE 4C | ||||

| 20(16/32) | 1x0.5 | 1.4 | 4.5 | 17 |

| 18(24/32) | 1x0.75 | 1.4 | 4.7 | 21 |

| 17(32/32) | 1x1 | 1.4 | 4.9 | 24 |

| 16(30/30) | 1x1.5 | 1.4 | 5.2 | 30 |

| 14(50/30) | 1x2.5 | 1.4 | 5.6 | 41 |

| 12(56/28) | 1x4 | 1.4 | 6.3 | 66 |

| 10(84/28) | 1x6 | 1.5 | 7.5 | 93 |

| 8(80/26) | 1x10 | 1.5 | 8.5 | 136 |

| 6(128/26) | 1x16 | 1.5 | 9.6 | 206 |

| 4(200/26) | 1x25 | 1.6 | 11.4 | 300 |

| 2(280/26) | 1x35 | 1.6 | 12.8 | 406 |

| 1(400/26) | 1x50 | 1.7 | 14.8 | 573 |

| 2/0(356/24) | 1x70 | 1.8 | 17.2 | 793 |

| 3/0(485/24) | 1x95 | 2 | 19.7 | 1028 |

| 4/0(614/24) | 1x120 | 2.2 | 21.9 | 1285 |

| 300 MCM (765/24) | 1x150 | 2.3 | 24.1 | 1562 |

| 350 MCM (944/24) | 1x185 | 2.4 | 26.3 | 1914 |

| 500MCM(1225/24) | 1x240 | 2.4 | 28.3 | 2431 |

| (1525/24) | 1x300 | 2.6 | 33 | 3024 |

| (2013/24) | 1x400 | 2.8 | 37.4 | 3948 |

| TYPE 4D | ||||

| 6(128/26) | 1x16 | 2.8 | 12.4 | 255 |

| 4(200/26) | 1x25 | 2.8 | 13.8 | 351 |

| 2(280/26) | 1x35 | 2.8 | 15.2 | 458 |

| 1(400/26) | 1x50 | 2.8 | 17.1 | 616 |

| 2/0(356/24) | 1x70 | 2.8 | 19.2 | 820 |

| 3/0(485/24) | 1x95 | 3 | 22 | 1097 |

| 4/0(614/24) | 1x120 | 3 | 23.5 | 1340 |

| 300 MCM (765/24) | 1x150 | 3 | 25.5 | 1635 |

| 350 MCM (944/24) | 1x185 | 3 | 27.5 | 1973 |

| 500MCM(1225/24) | 1x240 | 3 | 30.6 | 2504 |

| (1525/24) | 1x300 | 3 | 33.8 | 3098 |

| (2013/24) | 1x400 | 3 | 37.8 | 4045 |

| TYPE 4E | ||||

| 6(128/26) | 1x16 | 5 | 17.2 | 384 |

| 4(200/26) | 1x25 | 5 | 18.6 | 495 |

| 2(280/26) | 1x35 | 5 | 20 | 613 |

| 1(400/26) | 1x50 | 5 | 22.1 | 796 |

| 2/0(356/24) | 1x70 | 5 | 24.2 | 1020 |

| 3/0(485/24) | 1x95 | 5 | 26.3 | 1287 |

| 4/0(614/24) | 1x120 | 5 | 27.8 | 1542 |

| 300 MCM (765/24) | 1x150 | 5 | 29.8 | 1853 |

| 350 MCM (944/24) | 1x185 | 5 | 32.1 | 2225 |

| 500MCM(1225/24) | 1x240 | 5 | 35.1 | 2782 |

| TYPE 4F | ||||

| 6(128/26) | 1x16 | 7.6 | 22.9 | 566 |

| 4(200/26) | 1x25 | 7.6 | 24.1 | 680 |

| 2(280/26) | 1x35 | 7.6 | 25.5 | 810 |

| 1(400/26) | 1x50 | 7.6 | 27.3 | 997 |

| 2/0(356/24) | 1x70 | 7.6 | 29.4 | 1237 |

| 3/0(485/24) | 1x95 | 7.6 | 31.5 | 1520 |

| 4/0(614/24) | 1x120 | 7.6 | 33.3 | 1804 |

| 300 MCM (765/24) | 1x150 | 7.6 | 35.3 | 2131 |

| 350 MCM (944/24) | 1x185 | 7.6 | 37.3 | 2503 |

| 500MCM(1225/24) | 1x240 | 7.6 | 40.3 | 3081 |