| Industrial Cables | |||

Industrial Cables Multi-Core Flexible Cables

Industrial Cables Multi-Core Flexible Cables

680TQ to BS 6007

Application and Description

680TQ to BS 6007 cables are designed for temporary building sites as extension leads for portable or fixed

equipment. The copper braid prevents earth leakage and offers mechanical protection.

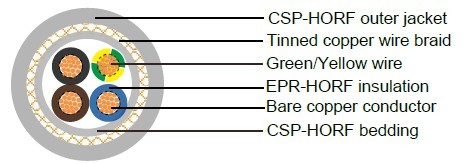

Cable Construction

Fine bare copper strands

Stranding to BS 6360 Class 5 or IEC 60228 Class 5

EPR-HOFR( Ethylene Propylene Rubber-Heat and Oil Resistant and Flame Retardant) insulation

CSP(Chlorosulphonated Polyethylene), HOFR (Heat and Oil Resistant and Flame Retardant) bedding

TCWB(tinned copper wire braid)

CSP(Chlorosulphonated Polyethylene), HOFR (Heat and Oil Resistant and Flame Retardant) sheath

Core Identification

2 cores: Brown, Blue

3 cores: Green/Yellow, Brown, Blue

4 cores: Green/Yellow, Brown, Black, Grey

5 cores: Green/Yellow, Blue, Brown, Black, Grey

6 cores and above: white insulation with black numerals

Technical Characteristics

Working voltage: 450/750 volts

Minimum bending radius: 8.0xOverall diameter (below 25mm²)

10xOverall diameter (above 25mm²)

Temperature Range: -20º C to +85º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩxkm

Cable Parameter

| AWG (No of Strands/ Strand Diameter) | No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Bedding mm |

Diameter of Braid Wire mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 6802TQ | |||||||

| 12(56/28) | 2x4 | 1 | 2 | 0.2 | 2.6 | 19.8 | 578 |

| 6803TQ | |||||||

| 12(56/28) | 3x4 | 1 | 2.2 | 0.2 | 2.8 | 21.3 | 684 |

| 10(84/28) | 3x6 | 1 | 2.4 | 0.3 | 3.1 | 24.8 | 955 |

| 8(80/26) | 3x10 | 1.2 | 3.1 | 0.3 | 3.8 | 30.7 | 1450 |

| 6(128/26) | 3x16 | 1.2 | 3.3 | 0.3 | 4 | 33.8 | 1840 |

| 4(200/26) | 3x25 | 1.4 | 3.6 | 0.4 | 4.4 | 39.6 | 2620 |

| 6804TQ | |||||||

| 12(56/28) | 4x4 | 1 | 2.3 | 0.3 | 3 | 23.6 | 874 |

| 10(84/28) | 4x6 | 1 | 2.6 | 0.3 | 3.3 | 27.1 | 1147 |

| 8(80/26) | 4x10 | 1.2 | 3.3 | 0.3 | 4 | 33.3 | 1730 |

| 6(128/26) | 4x16 | 1.2 | 3.5 | 0.4 | 4.2 | 37.2 | 2310 |

| 4(200/26) | 4x25 | 1.4 | 3.8 | 0.4 | 4.7 | 43.2 | 3170 |

| 2(280/26) | 4x35 | 1.4 | 4.1 | 0.4 | 5 | 47.9 | 3990 |

| 1(400/26) | 4x50 | 1.6 | 4.6 | 0.4 | 5.5 | 55.1 | 5320 |