| Thermocouple Cables | |||

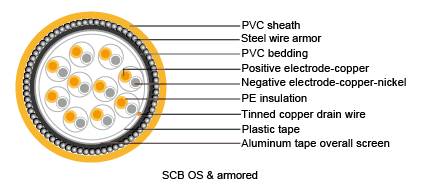

Single pair/multipair Overall Screen with Armor

Application

These cables are used in thermocouple circuits, petrochemical plants, utilities and industrial

plants.

Specification

Conductor: Solid

Type applicable: KX, EX, JX, TX, NX, KCA, KCB, RCA, RCB, SCA, RCB, BC

Insulation: PVC, PE, XLPE or LSZH thermoplastic material

Wrapping: At least 1 layer of plastic tape

Overall screen: 24 μm aluminium / PETP tape over 7-stranded tinned copper drain wire, 0.5

mm²

Bedding: PE, PVC or LSZH thermoplastic material

Armor: Galvanized round steel wires

Outer sheath: PVC or LSZH thermoplastic material

Color code: According to IEC 60584-3

Flame retardancy: IEC 60332-1

Flame propagation: IEC 60332 cat. C

Temperature range: -30°C up to 70°C during operation. -5°C up to 50°C during installation.

0.5 mm²

Conductor Size |

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

0.5 |

1 |

0.4 |

0.8 |

0.9 |

1.3 |

9.6 |

206 |

0.5 |

2 |

0.4 |

0.8 |

0.9 |

1.4 |

12.1 |

295 |

0.5 |

4 |

0.4 |

0.9 |

0.9 |

1.4 |

13.4 |

374 |

0.5 |

6 |

0.4 |

1.1 |

0.9 |

1.4 |

15.4 |

480 |

0.5 |

8 |

0.4 |

1.1 |

0.9 |

1.5 |

16.3 |

546 |

0.5 |

10 |

0.4 |

1.2 |

0.9 |

1.5 |

17.9 |

656 |

0.5 |

12 |

0.4 |

1.2 |

0.9 |

1.5 |

18.5 |

703 |

0.5 |

16 |

0.4 |

1.2 |

1.25 |

1.6 |

21.1 |

975 |

0.5 |

20 |

0.4 |

1.2 |

1.25 |

1.6 |

22.5 |

1093 |

0.5 |

24 |

0.4 |

1.3 |

1.25 |

1.7 |

24.3 |

1285 |

0.8 mm²

Conductor Size |

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

0.8 |

1 |

0.4 |

0.8 |

0.9 |

1.3 |

10.0 |

227 |

0.8 |

2 |

0.4 |

0.9 |

0.9 |

1.4 |

13.0 |

343 |

0.8 |

4 |

0.4 |

0.9 |

0.9 |

1.4 |

14.3 |

431 |

0.8 |

6 |

0.4 |

1.1 |

0.9 |

1.5 |

16.7 |

567 |

0.8 |

8 |

0.4 |

1.2 |

0.9 |

1.5 |

17.6 |

657 |

0.8 |

10 |

0.4 |

1.2 |

0.9 |

1.6 |

19.4 |

788 |

0.8 |

12 |

0.4 |

1.2 |

1.25 |

1.6 |

20.8 |

999 |

0.8 |

16 |

0.4 |

1.2 |

1.25 |

1.7 |

22.9 |

1175 |

0.8 |

20 |

0.4 |

1.3 |

1.25 |

1.7 |

24.8 |

1347 |

0.8 |

24 |

0.4 |

1.3 |

1.25 |

1.7 |

26.3 |

1556 |

1.0 mm²

Conductor Size |

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

1.0 |

1 |

0.4 |

0.8 |

0.9 |

1.3 |

10.3 |

240 |

1.0 |

2 |

0.4 |

0.9 |

0.9 |

1.4 |

13.4 |

366 |

1.0 |

4 |

0.4 |

1.1 |

0.9 |

1.4 |

15.1 |

489 |

1.0 |

6 |

0.4 |

1.2 |

0.9 |

1.5 |

17.4 |

629 |

1.0 |

8 |

0.4 |

1.2 |

0.9 |

1.5 |

18.2 |

720 |

1.0 |

10 |

0.4 |

1.2 |

1.25 |

1.6 |

20.9 |

1016 |

1.0 |

12 |

0.4 |

1.2 |

1.25 |

1.6 |

21.5 |

1094 |

1.0 |

16 |

0.4 |

1.3 |

1.25 |

1.7 |

24.0 |

1312 |

1.0 |

20 |

0.4 |

1.3 |

1.25 |

1.7 |

25.7 |

1490 |

1.0 |

24 |

0.4 |

1.3 |

1.25 |

1.7 |

27.3 |

1727 |

1.3 mm²

Conductor Size |

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

1.3 |

1 |

0.4 |

0.8 |

0.9 |

1.3 |

10.6 |

258 |

1.3 |

2 |

0.4 |

0.9 |

0.9 |

1.4 |

14.6 |

399 |

1.3 |

4 |

0.4 |

1.1 |

0.9 |

1.5 |

16.8 |

546 |

1.3 |

6 |

0.4 |

1.2 |

0.9 |

1.5 |

19.3 |

701 |

1.3 |

8 |

0.4 |

1.2 |

0.9 |

1.6 |

20.4 |

817 |

1.3 |

10 |

0.4 |

1.2 |

1.25 |

1.6 |

23.2 |

1136 |

1.3 |

12 |

0.4 |

1.2 |

1.25 |

1.7 |

24.2 |

1240 |

1.3 |

16 |

0.4 |

1.3 |

1.25 |

1.7 |

26.8 |

1484 |

1.3 |

20 |

0.4 |

1.3 |

1.25 |

1.7 |

28.9 |

1697 |

1.3 |

24 |

0.4 |

1.5 |

1.25 |

1.8 |

31.5 |

2025 |

1.5 mm²

Conductor Size |

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

1.5 |

1 |

0.5 |

0.8 |

0.9 |

1.3 |

11.2 |

284 |

1.5 |

2 |

0.5 |

1.1 |

0.9 |

1.4 |

16.1 |

467 |

1.5 |

4 |

0.5 |

1.2 |

0.9 |

1.5 |

18.3 |

627 |

1.5 |

6 |

0.5 |

1.2 |

0.9 |

1.6 |

21.2 |

802 |

1.5 |

8 |

0.5 |

1.2 |

1.25 |

1.6 |

22.9 |

1082 |

1.5 |

10 |

0.5 |

1.3 |

1.25 |

1.7 |

25.7 |

1319 |

1.5 |

12 |

0.5 |

1.3 |

1.25 |

1.7 |

26.6 |

1430 |

1.5 |

16 |

0.5 |

1.3 |

1.25 |

1.7 |

29.3 |

1697 |

1.5 |

20 |

0.5 |

1.5 |

1.25 |

1.8 |

32.4 |

2000 |

1.5 |

24 |

0.5 |

1.5 |

1.6 |

1.9 |

35.5 |

2598 |

*The number here is just approx. weight. It changes according to the insulation material and the conductor used in different type of extension cable and compensating cable.