| Thermocouple Cables | |||

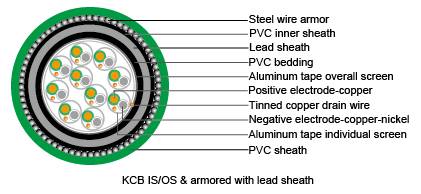

Multipair Individual/overall Screen with Armor and Lead Sheath

Applications

These cable can be used in cable tray or conduit to connect different types of thermocouple in industrial process controls, refineries, oil and gas plant. Excellent protection against corrosion, humidity and poor vibration resistance.

Specification

Conductor: Solid

Type applicable: KX, EX, JX, TX, NX, KCA, KCB, RCA, RCB, SCA, RCB, BC

Insulation: PVC, PE, XLPE or LSZH thermoplastic material

Individual screen: 24 μm aluminium / PETP tape over solid tinned copper drain wire, 0.6 mm

Wrapping: At least 1 layer of plastic tape

Overall screen: 24 μm aluminium / PETP tape over 7-stranded tinned copper drain wire, 0.5 mm²

Bedding: PE, PVC or LSZH thermoplastic material

Lead sheath: Lead alloy

Inner sheath: PVC or LSZH thermoplastic material

Armor: Galvanized round steel wires

Outer sheath: PVC or LSZH thermoplastic material

Color code: According to IEC 60584-3

Flame retardancy: IEC 60332-1

Flame propagation: IEC 60332 cat. C

Temperature range: -30°C up to 70°C during operation. -5°C up to 50°C during installation.

0.5 mm²

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Lead Sheath Thickness (mm) |

Inner Sheath Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

2 |

0.4 |

0.9 |

1.1 |

0.8 |

0.9 |

1.4 |

17.3 |

892 |

4 |

0.4 |

1.1 |

1.1 |

0.8 |

0.9 |

1.4 |

18.9 |

1078 |

6 |

0.4 |

1.2 |

1.1 |

0.8 |

0.9 |

1.5 |

21.2 |

1309 |

8 |

0.4 |

1.2 |

1.2 |

0.8 |

0.9 |

1.5 |

22.3 |

1491 |

10 |

0.4 |

1.2 |

1.2 |

0.8 |

1.25 |

1.6 |

25.4 |

1912 |

12 |

0.4 |

1.2 |

1.2 |

0.9 |

1.25 |

1.6 |

25.8 |

2000 |

16 |

0.4 |

1.3 |

1.3 |

0.9 |

1.25 |

1.7 |

28.2 |

2383 |

20 |

0.4 |

1.3 |

1.3 |

0.9 |

1.25 |

1.7 |

29.5 |

2610 |

24 |

0.4 |

1.3 |

1.4 |

1.0 |

1.25 |

1.8 |

32.6 |

3087 |

0.8 mm²

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Lead Sheath Thickness (mm) |

Inner Sheath Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

2 |

0.4 |

0.9 |

1.1 |

0.8 |

0.9 |

1.4 |

18.0 |

970 |

4 |

0.4 |

1.1 |

1.1 |

0.8 |

0.9 |

1.5 |

20.2 |

1204 |

6 |

0.4 |

1.2 |

1.1 |

0.8 |

0.9 |

1.5 |

22.3 |

1451 |

8 |

0.4 |

1.2 |

1.2 |

0.8 |

0.9 |

1.6 |

24.6 |

1848 |

10 |

0.4 |

1.2 |

1.2 |

0.9 |

1.25 |

1.6 |

26.9 |

2137 |

12 |

0.4 |

1.3 |

1.3 |

0.9 |

1.25 |

1.7 |

28.2 |

2383 |

16 |

0.4 |

1.3 |

1.3 |

0.9 |

1.25 |

1.7 |

30.0 |

2690 |

20 |

0.4 |

1.3 |

1.4 |

1.0 |

1.25 |

1.8 |

32.1 |

3092 |

24 |

0.4 |

1.5 |

1.4 |

1.0 |

1.25 |

1.8 |

35.2 |

3581 |

1.0 mm²

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Lead Sheath Thickness (mm) |

Inner Sheath Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

2 |

0.4 |

1.1 |

1.1 |

0.8 |

0.9 |

1.4 |

18.4 |

1011 |

4 |

0.4 |

1.1 |

1.1 |

0.8 |

0.9 |

1.5 |

20.2 |

1204 |

6 |

0.4 |

1.2 |

1.2 |

0.9 |

0.9 |

1.6 |

23.6 |

1691 |

8 |

0.4 |

1.2 |

1.2 |

0.9 |

1.25 |

1.6 |

24.6 |

1848 |

10 |

0.4 |

1.2 |

1.3 |

0.9 |

1.25 |

1.7 |

27.5 |

2244 |

12 |

0.4 |

1.3 |

1.3 |

0.9 |

1.25 |

1.7 |

28.2 |

2383 |

16 |

0.4 |

1.3 |

1.4 |

1.0 |

1.25 |

1.7 |

30.2 |

2781 |

20 |

0.4 |

1.5 |

1.4 |

1.1 |

1.25 |

1.8 |

32.5 |

3154 |

24 |

0.4 |

1.5 |

1.5 |

1.2 |

1.6 |

1.9 |

36.5 |

3982 |

1.3 mm²

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Lead Sheath Thickness (mm) |

Inner Sheath Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

2 |

0.4 |

1.1 |

1.1 |

0.8 |

0.9 |

1.5 |

19.8 |

1140 |

4 |

0.4 |

1.2 |

1.2 |

0.9 |

0.9 |

1.5 |

22.5 |

1588 |

6 |

0.4 |

1.2 |

1.2 |

1.0 |

1.25 |

1.6 |

25.1 |

1915 |

8 |

0.4 |

1.2 |

1.3 |

1.1 |

1.25 |

1.6 |

26.4 |

2190 |

10 |

0.4 |

1.3 |

1.3 |

1.1 |

1.25 |

1.7 |

29.7 |

2606 |

12 |

0.4 |

1.3 |

1.4 |

1.1 |

1.25 |

1.7 |

30.5 |

2843 |

16 |

0.4 |

1.3 |

1.4 |

1.2 |

1.25 |

1.8 |

32.5 |

3235 |

20 |

0.4 |

1.5 |

1.5 |

1.2 |

1.25 |

1.9 |

35.2 |

3797 |

24 |

0.4 |

1.5 |

1.5 |

1.2 |

1.6 |

1.9 |

39.5 |

4653 |

1.5 mm²

No. of Pairs |

Insulation Thickness (mm) |

Bedding Thickness (mm) |

Lead Sheath Thickness (mm) |

Inner Sheath Thickness (mm) |

Diameter of Armor Wire (mm) |

Outer Sheath Thickness (mm) |

Nominal O.D. (mm) |

Weight* (kg/km) |

2 |

0.5 |

1.1 |

1.2 |

0.9 |

0.9 |

1.5 |

21.1 |

1303 |

4 |

0.5 |

1.2 |

1.2 |

1.0 |

0.9 |

1.5 |

23.7 |

1741 |

6 |

0.5 |

1.2 |

1.3 |

1.1 |

1.25 |

1.6 |

26.9 |

2193 |

8 |

0.5 |

1.3 |

1.3 |

1.1 |

1.25 |

1.7 |

28.7 |

2481 |

10 |

0.5 |

1.3 |

1.4 |

1.2 |

1.25 |

1.7 |

31.9 |

2995 |

12 |

0.5 |

1.3 |

1.4 |

1.2 |

1.25 |

1.7 |

32.6 |

3164 |

16 |

0.5 |

1.5 |

1.5 |

1.3 |

1.25 |

1.9 |

36.3 |

3863 |

20 |

0.5 |

1.5 |

1.6 |

1.3 |

1.6 |

1.9 |

39.2 |

4686 |

24 |

0.5 |

1.7 |

1.6 |

1.3 |

1.6 |

2.0 |

43.6 |

5471 |

*The number here is just approx. weight. It changes according to the insulation material and the conductor used in different type of extension cable and compensating cable.