| Railway Cables | ||||||||||||

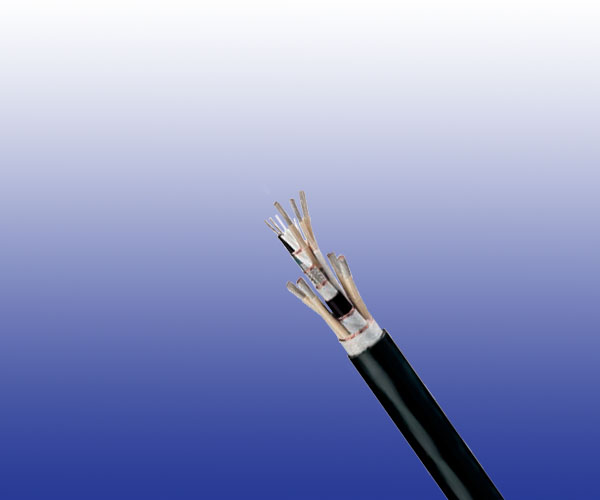

![]() Integrated 9/11/18/20 Cores 0.75mm² UIC Databus Cables

Integrated 9/11/18/20 Cores 0.75mm² UIC Databus Cables

Application

The cables are used as connecting cables to transmit digital signals inside railway rolling stocks.

Standards

● DIN 5510-1

Construction

For 9 cores UIC databus cables:

4 cores

10 mm² stranded tinned copper conductor with LSZH insulation.

Combined Element

3 cores (with Cu-strand 2×6mm², 1×2.5mm²) are twisted with a fi lling element to a combined element. Wrapping: Overlapped plasticfoil(s).

Elements sheaths: TPE

UIC Data Bus 0.75mm²

Two foam skin insulated tinned copper stranded conductors are twisted together with two filling elements to a pair.

Wrapping: Overlapped plastic-foil(s).

Screen: Tinned copper wire braid screen

Element sheaths: TPE.

Stranding

4 strands are twisted to a core together with 3 cored element, the UIC data bus and two fi llers

Core Wrapping

Overlapped plastic-foil(s).

Outer Sheath

Cross-linked oil resistant LSZH compound.

For 11 cores UIC databus cables:

4 cores

10 mm² stranded tinned copper conductor with LSZH insulation.

Combined Element

5 cores (with Cu-strand 2×6mm², 1×2.5mm² and 2×1.0 mm²) are twisted with a fi lling element to form a combined element.

Wrapping: Overlapped plastic-foil(s).

Elements sheaths: TPE.

UIC Data Bus 0.75mm²

Two foam skin insulated tinned copper r stranded conductors are twisted together with two fi lling elements to a pair.

Wrapping: Overlapped plastic-foil(s).

Screen: Tinned copper wire braid screen.

Element sheaths: TPE.

Wrapping: Overlapped plastic-foil(s).

Stranding

4 strands are twisted to a core together with 5 cored element, the UIC data bus and two fi llers.

Core Wrapping

Overlapped plastic-foil(s).

Outer Sheath

Cross-linked oil resistant LSZH compound.

For 18/20 cores UIC databus cables:

Star Quad

Four LSZH insulated 1mm² stranded tinned copper conductors are twisted to form a star quad.

UIC Data Bus 0.75mm²

Two foam skin insulated tinned copper stranded conductors are twisted together with two filling elements to form a pair.

Wrapping: Overlapped plastic-foil(s)

Screen: Tinned copper wire braid screen

Element sheaths: TPE.

Wrapping: Overlapped plastic-foil(s)

Stranding

4 star quads are stranded together with 2 or 4 UIC data bus cable and several fi llers.

Core Wrapping

Overlapped plastic-foil(s).

Screen

Tinned copper-wire braid screen.

Outer Sheath

Cross-linked oil resistant LSZH compound.

Electrical Characteristics at 20℃

| Nominal Cross Section | mm² |

0.75 |

1 |

2.5 |

6 |

10 |

| No of Strand/Strand Diameter | 19/0.22 |

19/0.25 |

37/0.29 |

84/0.3 |

80/0.4 |

|

| Maximum Conductor Resistant | Ω/km |

26.7 |

20 |

8.21 |

3.39 |

1.95 |

| Impedance@1.0-10MHz | Ω |

120+/-12 |

- |

- |

- |

- |

| Maximum Attenuation @1MHz | dB/km |

10 |

- |

- |

- |

- |

| Maximum Attenuation @1.5MHz | dB/km |

13 |

- |

- |

- |

- |

| Maximum Attenuation @2MHz | dB/km |

14 |

- |

- |

- |

- |

| Maximum Attenuation @3MHz | dB/km |

18 |

- |

- |

- |

- |

| Maximum Transfer Impedance | mΩ/m |

30 |

- |

- |

- |

- |

| Nominal Voltage Rating | v |

300 |

- |

- |

- |

- |

Mechanical and Thermal Properties

Minimum Bending Radius:6×OD (single); 12×OD (multiple)

Temperature Range:-40℃ to +100℃ (during operation); -20℃ +50℃ (during installation)

Dimensions And Weight

Cable Code |

No. of cores& Nominal Conductor Cross Sectional Area No.×mm² |

Nominal Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| RD-UIC-4C10S+2C6S+1C2.5S+2C0.75S | 4×10+2×6+1×2.5+2×0.75 |

1.8 |

25 |

917 |

| RD-UIC-4C10S+2C6S+1C2.5S+2C1S+2C0.75S | 4×10+2×6+1×2.5+2×1.0+2×0.75 |

1.8 |

25 |

969 |

| RD-UIC-4Q1S+2C0.75S | 4×4×1.0+ 2×0.75 |

1.8 |

18.5 |

498 |

| RD-UIC-4Q1S+2P0.75S | 4×4×1.0+ 2×2×0.75 |

1.8 |

23 |

530 |