Steel Wire Cable Tray-Tray Lengths & Ancillary Items

Cable trays are mainly exposed to atmospheric corrosion

Electroplated zinc to standard EN 12 329

The cable tray, manufactured using untreated steel wire, is pickled and then immersed in an

electrolyte containing zinc. Zinc is then deposited on it by passing an electric current. A smooth

bluish-grey, fairly glossy appearance is obtained depending on the pH value of the electrolytic bath

used. The colour and gloss have no negative or positive effect on the corrosion resistance of the

coating.

Hot dip galvanised after manufacture to standard BS EN ISO 1461 (formerly

BS729)

The cable trays or accessories manufactured from untreated steel sheet or wire are degreased

and pickled before being immersed in a bath of molten zinc. The whole part is therefore covered

with a thick layer of zinc.

Pre-galvanised steel to standard BS EN 10327: Grade DX51D

Before manufacture, a coating of zinc is deposited by continuous immersion on the steel sheets

or wires.

Stainless steel to standard BS EN 10088 : Number 1.4401 (equivalent to 316L)

Since it contains molybdenum, stainless steel 316L offers almost perfect corrosion resistance in

all types of industry, especially in highly aggressive halogen-containing environments (fluorine and

chlorine).

Dacromet

A coating based on zinc and aluminium is obtained, giving the parts a smooth, light grey

appearance with no grain. Dacromet offers protection equivalent to that of hot dip galvanised

after manufacture and is only used for small accessories and fixings, which are difficult to hot dip

galvanise.

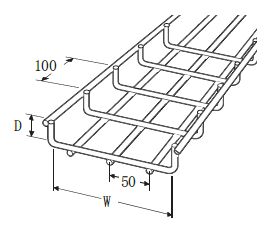

Straight Section

| Ordering Code | Width (W) | Depth (D) | Length | Ordering Code | Width (W) | Depth (D) | Length |

|---|---|---|---|---|---|---|---|

| mm | mm | m | mm | mm | m | ||

| Electroplated zinc | CSG300052 | 300 | 52 | 3 | |||

| CS050028 | 50 | 28 | 3 | CSG400052 | 400 | 52 | 3 |

| CS100028 | 100 | 28 | 3 | CSG450052 | 450 | 52 | 3 |

| CS150028 | 150 | 28 | 3 | CSG500052 | 500 | 52 | 3 |

| CS200028 | 200 | 28 | 3 | CSG600052 | 600 | 52 | 3 |

| CS300028 | 300 | 28 | 3 | CSG100102 | 100 | 102 | 3 |

| CS050052 | 50 | 52 | 3 | CSG200102 | 200 | 102 | 3 |

| CS100052 | 100 | 52 | 3 | CSG300102 | 300 | 102 | 3 |

| CS150052 | 150 | 52 | 3 | CSG400102 | 400 | 102 | 3 |

| CS200052 | 200 | 52 | 3 | CSG500102 | 500 | 102 | 3 |

| CS300052 | 300 | 52 | 3 | Stainless steel | |||

| CS400052 | 400 | 52 | 3 | CSS050028 | 50 | 28 | 3 |

| CS450052 | 450 | 52 | 3 | CSS100028 | 100 | 28 | 3 |

| CS500052 | 500 | 52 | 3 | CSS150028 | 150 | 28 | 3 |

| CS600052 | 600 | 52 | 3 | CSS200028 | 200 | 28 | 3 |

| CS100102 | 100 | 102 | 3 | CSS300028 | 300 | 28 | 3 |

| CS200102 | 200 | 102 | 3 | CSS050052 | 50 | 52 | 3 |

| CS300102 | 300 | 102 | 3 | CSS100052 | 100 | 52 | 3 |

| CS400102 | 400 | 102 | 3 | CSS150052 | 150 | 52 | 3 |

| CS500102 | 500 | 102 | 3 | CSS200052 | 200 | 52 | 3 |

| CS600102 | 600 | 102 | 3 | CSS300052 | 300 | 52 | 3 |

| Hot dip galvanised | CSS400052 | 400 | 52 | 3 | |||

| CSG050028 | 50 | 28 | 3 | CSS450052 | 450 | 52 | 3 |

| CSG100028 | 100 | 28 | 3 | CSS500052 | 500 | 52 | 3 |

| CSG150028 | 150 | 28 | 3 | CSS600052 | 600 | 52 | 3 |

| CSG200028 | 200 | 28 | 3 | CSS100102 | 100 | 102 | 3 |

| CSG300028 | 300 | 28 | 3 | CSS200102 | 200 | 102 | 3 |

| CSG050052 | 50 | 52 | 3 | CSS300102 | 300 | 102 | 3 |

| CSG100052 | 100 | 52 | 3 | CSS400102 | 400 | 102 | 3 |

| CSG150052 | 150 | 52 | 3 | CSS500102 | 500 | 102 | 3 |

Ancillary Items

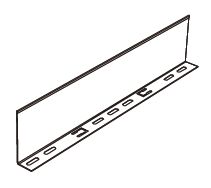

Dividers

| Ordering Code |

Applicable Tray Depth |

Length | Ordering Code |

Applicable Tray Depth |

Length |

|---|---|---|---|---|---|

| mm | mm | mm | mm | ||

| Pre-galvanised steel | CSDG052 | 52 | 3 | ||

| CSDC028 | 28 | 3 | CSDG102 | 102 | 3 |

| CSDC052 | 52 | 3 | Stainless steel | ||

| CSDC102 | 102 | 3 | CSDS028 | 28 | 3 |

| Hot dip galvanised | CSDS052 | 52 | 3 | ||

| CSDG028 | 28 | 3 | CSDS102 | 102 | 3 |

Divider connectors

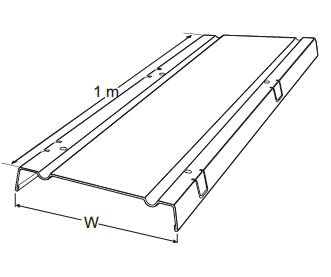

Covers

Can be fitted directly with integral tabs or alternatively with optional clips below

| Ordering Code | Width (W) | Ordering Code | Width (W) |

|---|---|---|---|

| mm | mm | ||

| Pre-galvanised steel | CSCG300 | 300 | |

| CSCC050 | 50 | CSCG400 | 400 |

| CSCC100 | 100 | CSCG450 | 450 |

| CSCC150 | 150 | CSCG500 | 500 |

| CSCC200 | 200 | CSCG600 | 600 |

| CSCC300 | 300 | Stainless steel | |

| CSCC400 | 400 | CSCS050 | 50 |

| CSCC450 | 450 | CSCS100 | 100 |

| CSCC500 | 500 | CSCS150 | 150 |

| CSCC600 | 600 | CSCS200 | 200 |

| Hot dip galvanised | CSCS300 | 300 | |

| CSCG050 | 50 | CSCS400 | 400 |

| CSCG100 | 100 | CSCS450 | 450 |

| CSCG150 | 150 | CSCS500 | 500 |

| CSCG200 | 200 | CSCS600 | 600 |

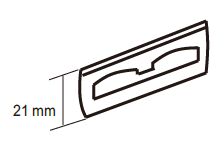

Clips

| Ordering Code | Applicable Tray Depth |

|---|---|

| mm | |

| Pre-galvanised steel | |

| CSCPC028 | 28 |

| CSCPC102 | 52 and 102 |

| Stainless steel | |

| CSCPS028 | 28 |

| CSCPS102 | 102 |