BS5308 Cable Part 1 Type1 MG-XLPE-OS-LSOH

Applications

BS5308 Cable Part 1 Type1 unarmoured fire resistant versions (Part 1 Type 1) are typically used in chemical and process industries where there is danger of fire.

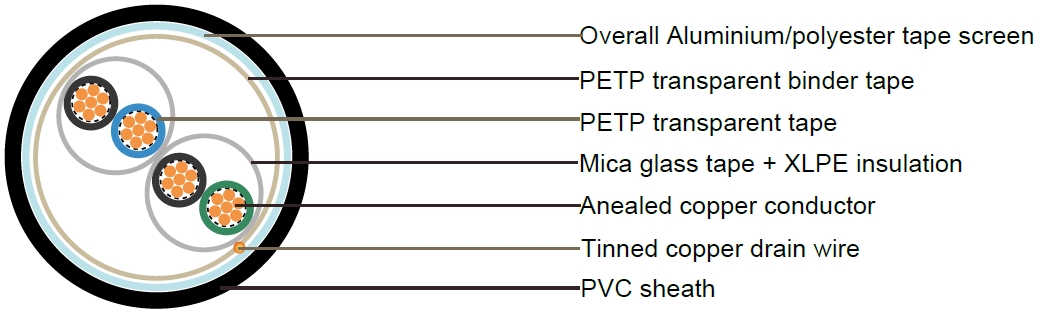

Construction

| Conductor | Annealed or tinned copper, Class 2 |

| Insulation | Mica glass tape, XLPE (Cross Linked Polyethylene), or PE (optional) |

| Pairing | Two insulated conductors uniformly twisted together with a lay not exceeding 100mm |

| Colour code | See technical information |

| Binder tape | PETP transparent tape |

| Collective screen | Aluminium/polyester tape is applied over the laid up pairs metallic side down in contact with tinned copper drain wire, 0.5mm² |

| Outer sheath | LSOH(Low Smoke Zero Halogen) sheath |

| Flame retardant to IEC60332-3-22 | |

| Fire resistant to IEC60331 | |

| Halogen free to IEC60754-1 | |

| Low smoke emission to IEC61034-1-2 | |

| Sheath colour | Black or blue |

Mechanical and Electrical Properties

| Operating temperature | -20˚C up to + 90˚C( fixed installation) |

| 0˚C to +50˚C(during operation ) | |

| Minimum bending radius | 5 x overall diameter |

| Conductor Area Size | mm² | 0.5 | 0.75 | 1.0 | 1.5 | |

| Conductor Stranding | No. x mm | 7 x 0.3 | 7 x 0.37 | 7 x 0.44 | 7 x 0.53 | |

| Conductor resistance max | ohm/km | 36 | 24.5 | 18.1 | 12.1 | |

| Insulation resistance min | Gohm/km | 5 | 5 | 5 | 5 | |

| Capacitance unbalance at 1 kHz(pair to pair screen) | pF/250m | 250 | ||||

| Max. Mutual Capacitance @ 1 kHz forNon OS or OS cables (except one-pair and two-pairs) | pF/m | 115 | 115 | 115 | 115 | |

| Max. Mutual Capacitance @ 1 kHz IS/OS cables (include 1 pair and 2 pair) | pF/m | 75 | 75 | 75 | 75 | |

| Max. L/R Ratio for adjacent cores(Inductance/ Resistance) | μH/ohm | 25 | 25 | 25 | 40 | |

| Test voltage | Core to core | V | 1000 | 1000 | 1000 | 1000 |

| Core to screen | V | 1000 | 1000 | 1000 | 1000 | |

| Rated voltage max | V | 300/500 | 300/500 | 300/500 | 300/500 | |

Parameter

| No.of Pairs | No.and Dia. of Wires | Nominal Conductor Cross-Sectional Area | Nominal Thickness of Insulation | Nominal Thickness of Sheath | Nominal Dia. of Cable | Approx. Weight |

|---|---|---|---|---|---|---|

| no./mm | mm² | mm | mm | mm | kg/km | |

| 1 | 7/0.44 | 1 | 0.6 | 1.4 | 7.8 | 89 |

| 2 | 7/0.44 | 1 | 0.6 | 1.4 | 9.2 | 121 |

| 5 | 7/0.44 | 1 | 0.6 | 1.4 | 13.9 | 298 |