PHOTOFLEX Photovoltaic Cable

Applications

These cables are designed for connecting photovoltaic system components inside and outside of buildings and equipment with high mechanical requirements and extreme weather conditions.

Standards

2PfG 1169/08.2007 (PV1-F)

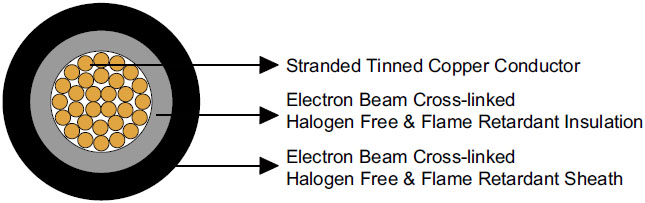

Construction

| Conductor |

Stranded tinned copper conductor per DIN VDE 0295 and IEC 60228 Class 5 |

| Insulation |

Electron beam cross-linked, halogen free and flame retardant compound |

| Sheath |

Electron beam cross-linked, halogen free and flame retardant compound, Black |

Electrical Properties

| Rated Voltage U0/U |

0.6/1 kV AC; 0.9/1.5 kV DC |

| Maximum Permitted DC Voltage |

1.8 kV DC (conductor/conductor, non earthed system, circuit not under load) |

| Insulation Resistance |

1000 MΩ-km |

| Spark Test |

6000 Vac (8400 Vdc) |

| Voltage Withstand |

6500 Vac for 5 min |

Thermal Properties

| Maximum Voltage |

|

| Ambient Temperature |

-40℃ ~ +90℃ |

| Maximum Temperature At Conductor |

120℃ (20000h) according to IEC/EN 60216-1 |

| Short Circuit Temperature |

200℃/5 sec |

| Thermal Endurance Test |

According to EN 60216-2 (temperature index +120° C) |

| High Temperature Pressure Test |

According to EN 60811-3-1 |

| Damp-Heat Resistance |

According to EN 60068-2-78 with 85% humidity |

Mechanical Properties

| Minimum Bending Radius |

4×OD (fixed), 5×OD (flexing) |

| Dynamic Penetration |

According to 2 PfG 1169/08.2007 Annex F |

| Notch Propagation |

According to 2 PfG 1169/08.2007 Annex G |

| Tensile Strength And Elongation Of Insulation And Jacket |

According to EN 60811 |

| Anticipated Period Of Use |

25 years |

Chemical Properties

| Ozone Resistance |

According to EN 50396 part 8.1.3 Method B |

| Weathering- UV Resistance |

According to HD 605/A1 |

| Ammoniac resistant |

| Very good resistance to oils and chemicals |

| High wear and robust, abrasion resistant |

| Acid & Alkaline Resistance |

According to EN 60811-2-1 (Oxal acid and sodium hydroxide) |

EC directives

The cables are conform to the EC directives CE 2006/95/EC (Low voltage directive) and RoHS 2002/95/EC (Restriction of Hazardous Substances)

Fire Performance

| Flame retardant according to EN 50265-2-1, IEC 60332-1, VDE 0482-332-1-2, DIN EN 60332-1-2 |

| Low smoke emission according to IEC 61034, EN 50268 |

| Halogen free according to EN 50267-2-1, IEC 60754-1 |

| Low corrosivity of gases according to EN 50267-2-2, IEC 60754-2 |

Dimensions and Weight

| No. of Cores × Nominal Cross Section |

No. of Stranding |

Nominal Conductor Diameter |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Nominal Overall Diamater |

Nominal Weight |

| No. ×mm^2 |

|

mm |

mm |

mm |

mm |

kg/km |

| 1×1.5 |

30/0.25 |

1.58 |

1.14 |

0.82 |

5.4 |

52 |

| 1×2.5 |

50/0.25 |

2.04 |

1.14 |

0.82 |

5.8 |

67 |

| 1×4.0 |

56/0.30 |

2.59 |

1.14 |

0.82 |

6.4 |

87 |

| 1×6.0 |

84/0.30 |

3.17 |

1.14 |

0.82 |

7.0 |

113 |

| 1×10 |

78/0.40 |

4.07 |

1.52 |

0.82 |

8.6 |

178 |

| 1×16 |

128/0.40 |

5.22 |

1.52 |

0.82 |

9.8 |

254 |

| 1×25 |

199/0.40 |

6.51 |

1.52 |

0.82 |

11.1 |

363 |

| 1×35 |

279/0.40 |

7.71 |

1.52 |

0.82 |

12.3 |

473 |

Current Carrying Capacity

| Cross Section |

AWG |

Maximum Conductor Resistance @ 20℃ |

Current Carrying Capacity |

| Single cable free in air |

Single cable on surfaces |

To cables adjacent on surfaces |

| mm^2 |

- |

Ω |

A |

A |

A |

| 1.5 |

16 |

13.7 |

30 |

29 |

24 |

| 2.5 |

14 |

8.21 |

41 |

39 |

33 |

| 4 |

12 |

5.09 |

55 |

52 |

44 |

| 6 |

10 |

3.39 |

70 |

67 |

57 |

| 10 |

8 |

1.95 |

98 |

93 |

79 |

| 16 |

6 |

1.24 |

132 |

125 |

107 |

| 25 |

4 |

0.795 |

176 |

167 |

142 |

| 35 |

2 |

0.565 |

218 |

207 |

176 |

Conversion Factor for Deviating Temperatures

| Ambient Temperature ℃ |

Conversion Factor |

| Up to 60 |

1.00 |

| 70 |

0.91 |

| 80 |

0.82 |

| 90 |

0.71 |

| 100 |

0.58 |

| 110 |

0.41 |

Reduction factor for accumulation according to IEC 60364-5-52, Table B.52-17