| Railway Cables | ||||||||||||

![]() Category 5E Data Cables

Category 5E Data Cables

Application

The cables are designed for permanently protected installation, inside and outside railway rolling stock, buses and other vehicles to connect fixed parts. Ethernet based networks as: infotainment, multimedia, passenger information system etc.

Standards

● DIN 5510-2

● EN 50228-2-2

● BS 6853

● EN 50306-3 par 4.8/4.9/4.10

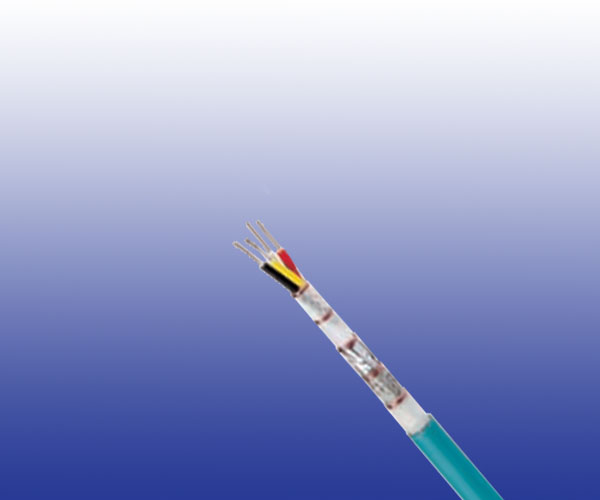

Construction

For 4×0.5mm², 4×22AWG cables:

Conductors

Stranded tin platedcopper conductor (for 0.5mm² cables) or stranded silver plated copper conductor (for 22AWG cables) according to IEC 60228 class 5.

Insulation

Electron beam crosslinkable compound.

Cable Element

Individual conductor stranded together.

EMC Screen1

Plastic laminated aluminium-tape.

EMC Screen2

Tinned copper braid.

Separator (s)

Plastic tape.

Outer Sheath

Electron beam crosslinkable compound.

For 4×2×22AWG cables:

Center

PE fi ller.

4 pairs 2×22AWG

Stranded tinned copper conductor according to IEC 60228 class 5.

Insulation

Electron beam crosslinkable compound.

EMC Screen1

Plastic laminated aluminium-tape.

EMC Screen2

Tinned copper braid.

Separator(s)

Plastic tape.

Outer Sheath

Electron beam crosslinkable compound.

Electrical Characteristics at 20℃

| Nominal Cross Section | mm² |

0.5 |

- |

| AWG |

|

- |

22 |

| Nominal Conductor Resistance | Ω/km |

40.1 |

54.4 |

| Maximum Resistance Unbalance | Ω/km |

1.1 |

1.1 |

| Maximum Capacitance |

|

|

|

| Core to Core | pF/m |

65 |

65 |

| Core to Screen | pF/m |

100 |

100 |

| Characteristic Impedance @100MHz | Ω |

100+/-5 |

100+/-5 |

| Transfer Impedance f≤30MHz | mΩ/m V |

200 |

200 |

| Nominal Voltage Rating | 300 |

300 |

Mechanical and Thermal Properties

Minimum Bending Radius:6×OD

Temperature Range:-40℃ to +90℃

Dimensions And Weight

Cable Code |

No. of cores& Nominal Conductor Cross Sectional Area No.×mm² |

Nominal Diameter of Strands No/mm |

Nominal Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

RD-Cat5E-4C0.5S |

4×0.5 |

19/0.18 |

1.2 |

8.3 |

102 |

RD-Cat5E-4C22A |

4×22AWG |

19/0.16 |

1.2 |

7.25 |

81 |

RD-Cat5E-4P22A |

4×2×22AWG |

19/0.16 |

1.2 |

12.6 |

174 |