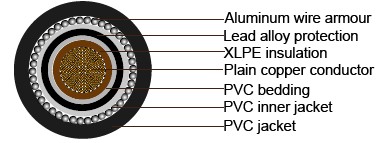

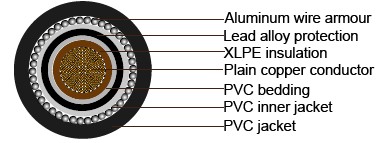

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications, in moist areas, where hydrocarbon and mechanical protections are needed and are protected against solvent penetration and corrosive attacks. The lead cover brings an enhanced resistance to aromatic hydrocarbons.

| Conductor |

Stranded copper conductor, Class 2 to BS 6460, IEC 60228. |

| Insulation |

XLPE (Cross-Linked Polyethylene) Type GP 8 or ethylene propylene rubber (GP 6) |

| Colour Code |

1 Core : Brown |

| 2 Cores : Brown or Blue |

| 3 Cores : Brown, Black, Grey |

| 4 Cores : Blue, Brown, Black, Grey |

| 5 Cores : Green/Yellow, Blue, Brown, Black, Grey |

| Above 5 Cores : White Cores with black numerals |

| Bedding |

PVC (Polyvinyl Chloride) |

| Protection |

LC (Lead alloy 'E') sheathed |

| Inner Sheath |

PVC (Polyvinyl Chloride) |

| Armour |

Single Core : AWA (Aluminum Wire Armour) |

| Multi Core : SWA (Steel Wire Armour) |

| Outer Sheath |

PVC(Polyvinyl Chloride), or anti-rodent and anti-termite PVC(optional) |